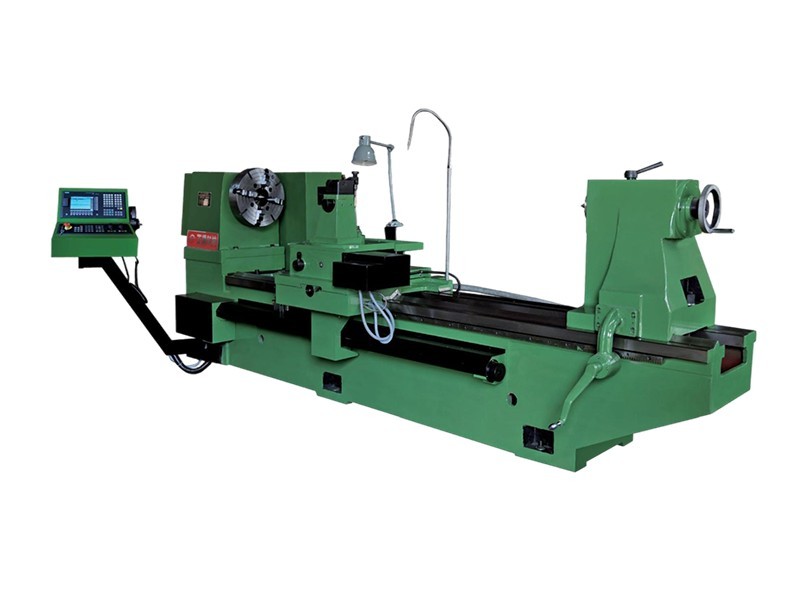

XK9350ZF-1 (Integrated Flying Type) CNC Roller Crescent Slot Milling Machine

The main products are: XK9350 series numerical control roll milling machine, CA(K)8450 series roll lathe, XKV1850(XKV2250) strong iron bed, XKW1850(XKW2250) strong horizontal milling machine, X5040(X53K), X5032(X52K) vertical milling machine X6140(X63W), X6132(X62W) horizontal milling machine, X6325 series universal rocker milling machine, etc.

Category: Milling machine

Key words: numerical control equipment, special machine tools, strong milling machine, numerical control roll milling machine, strong horizontal milling machine

Main Technical Parameters

| Project | XK9350ZF-1 |

| Maximum Diameter of Processed Roll | Φ100-Φ500mm |

| Maximum Length of Processed Roll | 2500mm |

| Applicable Specifications for Rebar | Φ6-Φ50mm |

| Cutting Method | Swing milling, 'Flying knife' grooving |

| Spindle Speed of Milling Head | 0-500rpm/2.0kw, 2000-10000rpm/2.2kw (Flying knife/milling head) |

| Minimum Feed Amount | 0.001mm (Servo) |

| Spindle Head Push Hole | MT5# |

| Chuck for Spindle Head | Φ400mm |

| CNC System | Mitsubishi digital control system, Japan |

| Main Motor Power Supply | 380V/50HZ |

| Machine Dimensions (Length × Width × Height) | 4000×1580×1900 |

| Machine Weight | 4700kg |

| Note | Ordinary material rolls, high-speed steel rolls, composite rolls, carbide roll rings |

Machine Usage Characteristics

XK9350ZF-1 series CNC roll crescent slot milling machine, suitable for processing crescent slots and equal height rib slots of hot-rolled ribbed steel bars for concrete with diameters from 6mm to 50mm. It features high automation, high processing accuracy, high cutting efficiency, convenient operation, safety and reliability, and low labor intensity, making it more suitable for processing carbide tungsten roll rings, high-speed steel rolls, and composite rolls. It can mill slots and engrave characters, making it a versatile machine.

● The machine bed, headstock, and other main components are of a closed frame structure, providing high rigidity and good shock resistance;

● The machine bed uses guide rails with ultrasonic quenching, ensuring good precision retention.

● It adopts a high-performance CNC system, capable of automatically cutting crescent slots with different rotation directions and any rise angle;

● It can automatically perform any equal division or spacing, automatically engraving factory specifications and grade markings (can engrave 26 English letters and numbers 0-9)

● Uses specialized cutting tools for high-speed cutting in one forming. Compared to traditional methods of processing roll crescent slots, it has high efficiency. The quality of the processed rolls is high, ensuring that the rebar meets the size and precision requirements of GB1499-1988 standard.

The main products are: XK9350 series numerical control roll milling machine, CA(K)8450 series roll lathe, XKV1850(XKV2250) strong iron bed, XKW1850(XKW2250) strong horizontal milling machine, X5040(X53K), X5032(X52K) vertical milling machine X6140(X63W), X6132(X62W) horizontal milling machine, X6325 series universal rocker milling machine, etc.

关键词: XK9350ZF-1 (Integrated Flying Type) CNC Roller Crescent Slot Milling Machine